|

|

Post by tractor284 on Feb 9, 2008 8:56:17 GMT -5

Great work!!! and great pics. I was wondering if you checked the valves for gpm rating and the rest of the system to make sure it will handle 2X the flow it was designed for?

PJ

|

|

|

|

Post by tuffytractor on Feb 9, 2008 13:36:06 GMT -5

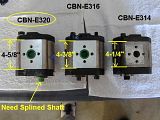

Hey Guys, My new 320 Gear Pump finally arrived from China, thought you might like to see the differences from the inside out.   (stole this updated better picture from Larry, shhhhhh don't tell him) From Left to right is the CBN- E320, CBN- E316, CBN- E314, don't know if its discernible in the photo but the sizes of the body are 4 5/8", 4 3/8", 4 1/4" respectively. Also, if you note the name plate is facing the same direction for the two on the right the 316 & 314. The 320 direction of the pressure side needs to be reversed, I've also heard this described as "re-clocked". The exit ports are 2 3/16", 2 1/8", 2" from the front face respectively. Here is a picture of the differential in size of the gears between the 320 & the 314. You can see how the 320 (20 Milliliters per rotation compared with 14 Milliliters) will move almost 43% more volume than the 314.   To re-clock the pump you orient the E shaped washers so they point to the pressure side exit and away from the inlet port, in this case the rear of the pump. This illustrates the flow of hydraulic fluid through the pump.   Then bolt it in.  Initially when I installed my 4 in 1 loader, I had between 18 - 22 seconds (depending on RPM's) from ground to top of lift. Mainly due to the over-sized cylinders (3.25") that came with my FEL. When I changed the FEL valve, I improved the speed down to 14 seconds @ 1800 RPM, finally with the new pump @ 1800 RPM, the same lift takes 8 seconds. Short of reducing the size of the main lift cylinders, I think I've attained the best time I can achieve and I think quite a usable result. I don't know whether I'm accurate or not, but my calculations (20 Milliliters *2000 rpm's)suggest that my new system is pushing 10.56 gpm, which is at capacity for the quick connects I have in the system. While I had my tractor up at my property, I did pick up some fairly large logs to test the strength of the jaws and the lifting capacity, all seemed to work fine. Now I'll get to try it again without waiting so long for the lift . |

|

GuglioLS

Administrator  Jinma354 LE

Jinma354 LE

Posts: 1,276

|

Post by GuglioLS on Feb 10, 2008 1:35:29 GMT -5

(stole this updated better picture from Larry, shhhhhh don't tell him)Busted! The truth is that one pump picture I used is Tim's. I stole it from him without permission! I am so busted. Hey thanks Tim for letting me "borrow" that to doctor up for you. What a swell guy to "let" me do that.  The good news is we both got better performance. Great mod Tim, I'm glad you pointed out you can "clock" the pumps to rotate in which ever direction needed for your engine. When I saw the spec's on the 320 I was concerned it would not hold up to 2300 psi. So far so good. Man, you went from 22 seconds to 8 seconds, that is huge! Larry

|

|

GuglioLS

Administrator  Jinma354 LE

Jinma354 LE

Posts: 1,276

|

Post by GuglioLS on Feb 10, 2008 1:54:47 GMT -5

Great work!!! and great pics. I was wondering if you checked the valves for gpm rating and the rest of the system to make sure it will handle 2X the flow it was designed for? PJ PJ,  no and probably not, but hey, it hasn't blown up yet. Not sure if the Chinese even know what capacity it's designed for. One thing I know for sure, the hoses are not blowing any time soon, they are all US made hoses, rated at lease 3000 psi. All of my hydraulic mods have valves rated at least 10 GPM most are in the 25GPM range so I should be covered in that respect. The one thing that may be of concern is the flow rate back into the TPH. Not sue if that's being exceeded or not. But so far the TPH seems to work normal. PJ are you considering any mods or upgrades? Larry |

|

biggkidd

CTW Expert

A World Away!!!

A World Away!!!

Posts: 226

|

Post by biggkidd on Feb 10, 2008 21:41:50 GMT -5

Tim, You and I have the same engine. I have been wanting to do this mod. I am assuming you haven't had problems with the input shaft? I ask because I was advised not to on count of the key way made different on the input shaft. About how many hours have you put on now since you made this change? Thanks KIDD  |

|

Jake

CTW Member

I love the smell of diesel in the morning. Smells like.. Victory!

I love the smell of diesel in the morning. Smells like.. Victory!

Posts: 58

|

Post by Jake on Feb 11, 2008 5:08:53 GMT -5

...with the slotted shaft for my 354c kama as it uses the same type as the 4 cyl jinma. Right now I've got a 314... Baknblack, is your main hyd. pump on the engine? ..or on the rear of the machine. (like b/h pump) ? My Kama TS354C (4 cyl) has it on the rear... above the pto shaft. The only hyd pump I have on the engine is for pwr steering. ..also.. does anyone know if the PTO pumps are driven at a different speed compared to the ones on the front of the engine? ..because I could have sworn the tag on mine showed it as a 306.  |

|

|

|

Post by baknblack on Feb 11, 2008 6:11:05 GMT -5

is your main hyd. pump on the engine? ..or on the rear of the machine. (like b/h pump) ? Rear, exactly like yours. Sorry for the late reply. I tend to miss some posts because of the software. |

|

Jake

CTW Member

I love the smell of diesel in the morning. Smells like.. Victory!

I love the smell of diesel in the morning. Smells like.. Victory!

Posts: 58

|

Post by Jake on Feb 12, 2008 7:12:26 GMT -5

Rear, exactly like yours. Sorry for the late reply. I tend to miss some posts because of the software. no prob... and.. I'm gonna have to go look at mine again... |

|

|

|

Post by tractor284 on Feb 12, 2008 7:47:36 GMT -5

Hi Larry:

I sure hope it does'nt blow up. But what I was thinking is heat build as it's going through the system. But all you have to do is put your hand on the pump after it's been run for a while to see how hot it gets. I'm always thinking of mods but just don't have the time.

PJ

|

|

|

|

Post by affordable on Feb 10, 2012 17:40:44 GMT -5

I now also have E-320 Pumps for the 200 Series Jinma tractors with the short slotted shaft, for more Information give me a call or e-mail tommy@affordabletractorsalesco.com Tommy Affordable Tractor Sales "Your Jinma Parts Superstore" www.affordabletractorsalesco.com |

|

nuno

CTW Member

Posts: 26

|

Post by nuno on Feb 11, 2012 4:59:35 GMT -5

Hey Tommy,

did you have the E-320 Pump also with the long splined Shaft for the 200 Series ?

|

|

|

|

Post by affordable on Feb 21, 2012 6:43:28 GMT -5

Yes ,I do have the 320 pumps with the long shaft ? Does yours have the 4-bolt mounting plate, and the long shaft ? Which engine do you have ? if yes it will bolt right on Tommy Affordable Tractor Sales "Your Jinma Parts Superstore" www.affordabletractorsalesco.com |

|

nuno

CTW Member

Posts: 26

|

Post by nuno on Feb 21, 2012 11:02:24 GMT -5

Hey Tommy, i have the KM 385 Laidong Engine. The Pump have the Steel Face Plate like the one shown in the Picture  with outlet in the Back Plate. I have a few Spare Parts for the Pump so it's no problem to replace the 4-bolt mounting plate to the Steel Plate. |

|

|

|

Post by affordable on Feb 21, 2012 11:40:55 GMT -5

Yes we have the pump, if you look under Hydraulics Larry G. has a hydraulic pump upgrade section that will tell you excatly what you need to do Tommy Affordable Tractor Sales "Your Jinma Parts Superstore" www.affordabletractorsalesco.com |

|