|

|

Post by sokkerbob on Mar 29, 2008 18:41:11 GMT -5

Hello everyone,

I have been reader of this forum (and previous) since I purchased my Jinma 354 about a year and half ago. Thanks to all of you for all your excellent advice, mods, etc.

I have a problem that I need some help with. While I was working on tractor, it started popping out of low gear. Eventually, it would not even go into low gear. I talked to Tommy @ Affordable and Ronald @ Ranch Hand Supply and they both suspected a bent shifting fork.

Well, it turned out it is not the shifting fork, but the pinion bearing has started coming out of the case and is preventing the sliding gear from engaging. We suspect the circlip in front of the bearing is probably the culprit.

My brother and I have split the tractor and removed the lifter box in order to have a good look. What we need help on is procedure for disassembling the transmission. Does anybody know how to remove the upper and lower shaft in the transmission? Any ideas or thoughts would be appreciated.

Bob

|

|

GuglioLS

Administrator  Jinma354 LE

Jinma354 LE

Posts: 1,276

|

Post by GuglioLS on Mar 29, 2008 23:11:05 GMT -5

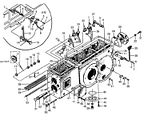

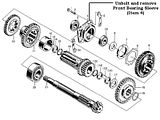

Bob, Bummer about that. When you say it will not go into low gear, does that mean it will not go into low range? I am very curious about the gearing in your 354. PLEASE take and post many pictures. We all need to see your repair efforts so as to learn all about it. You have an incredible opportunity to share a wealth of information for all of us here on the forum. So Please take the time to post pictures and a description of everything. I will do the best I can, I have not taken mine apart, but have looked into my Jinma 354 transmission several times and have taken many pictures of all the gears. To remove the upper and lower shafts, the transmission will need to be completely dismantled. Remove the bell housing from the front of the transmission, if you have not already done so. Drive out all roll pins for all shifter forks, remove the shifter fork slider shafts, then the slider forks. Unbolt the front bearing retainer flanges, pull out the shaft a little at a time while lifting out the gears. There are many parts bushings, bearings, gears, etc so be very careful to note how it comes apart so it can go back together properly. Here are a few pictures- the first one is a top view standing on the right side of the tractor looking down into the Transmission of my Jinma 354 . The following pics are from the parts manual to aid you in how everything is put together. Does your transmission look EXACTLY like the "live" picture of mine? Please pay particular attention to the reverse idler and the configuration of all the gears. I have been trying to find out if Jinma has two versions of the 354 transmission. So far no one has been able to give me any straight answers. The parts book shows several gear options and "user selectable" gears. But no one knows exactly what combination of gears are needed and what it does to the ratios. I would love to SLOW DOWN my tractor, it is WAY too fast in the Hi range. I suspect yours is too - Is that right? especially reverse, what do you think of the reverse speed in high range?       I am willing to help the best I can, please reciprocate by posting a boat load of pictures. Thanks, Larry |

|

|

|

Post by sokkerbob on Mar 30, 2008 9:46:29 GMT -5

Larry,

Thanks for reply. Here are answers to your questions.

Correct, it will not go into low range. As mentioned, I assumed it was problem with shifter fork, but it actually the pinion bearing that has moved forward to front of tractor about 3/4" in the case.

Yes it appears to be exactly the same. Also, your parts diagrams and part numbers are exactly the same as yours. My parts book has another set of diagrams for tractors without dual stage clutch, but I do not show any other gear options.

Yes that is right. Reverse in High range is out of control!!

I have pretty much followed steps that you mention in disassembly.

However, the shafts do not slide out. This is where we decided to stop and ask for advice. It appears that all of the bearings have been pressed onto shafts and into case and/or gear. We destroyed one of the roller bearings (Ser. No. 3 in diagram) on lower shaft (Drive Gearbox Main Shaft) trying to remove it. On the upper shaft, (Drive Gearbox Primary Shaft)we carefully pounded out the front roller bearing(Ser. No. 15) from case, but it is still tight on the primary shaft and shaft appears to be tight on rear roller bearing(Ser. No. 19) which appears to be pressed into the Twin gear for high-low speed. (Ser. No. 21).

Studying the lower shaft, it looks like it also has to come out of back of tractor which means disassembly of the differential. Fun, fun, fun

I took some pictures and will take a few more when it gets light out to illustrate.

Thanks again,

Bob

FYI, it looks like the way to slow down tractor would be to replace the high low speed gears on top shaft and lower shaft with different gears. This means we would have to see if such a combination is available from factory. Unless you have to disassemble for some other reason, probably would advise to just live with the wild ride in reverse.

|

|

|

|

Post by sokkerbob on Mar 30, 2008 11:14:35 GMT -5

As promised, Here are pictures when we first split transmission from bell housing.   The next set show disassembly so far. We have removed shifter forks, reverse idler, front bearing holders and attempted to remove front bearings. I have noted how pinion bearing has moved from case and how bearings appear pressed onto shaft.     Last picture is of differential. This is way I think the lower shaft will have to come out. The round tubes are the shifter rails that were slid back from transmission case.  Bob And just to put a pretty face to a name Me and my five grandsons taken about 1 year ago @ Fort Flagler, WA. Two more grandchildren due in July. One will be a boy, the other will not be known until b-day.  |

|

psj12

CTW Member

KAMA 554

KAMA 554

Posts: 93

|

Post by psj12 on Mar 30, 2008 14:52:35 GMT -5

Great looking prodigy! Sorry I can't help with the transmission problem but it will make a very interesting thread however you proceed.

|

|

3RRL

Administrator  Huge Kama

Huge Kama

Posts: 2,027

|

Post by 3RRL on Mar 30, 2008 15:14:48 GMT -5

Bob, I agree ... a great looking bunch you have there...and welcome to the forum.

Regarding the transmission, there is something wrong if those bearings fit the shafts so tight. That would make an assembly nightmare! How would you ever position them if you couldn't move them into location once the shaft is in the housing?

Seeing what you are going through, my hat is off to you and your brother for tackling that job. I might have been tempted to tap that bearing which moved out of it's retainer pocket back into place and installed a press fit dowel to keep it there or a SHCS to retain the flange.

With the bearings being tight, you might ruin them upon disassembly, much like that one you talked about. Is there a way for you to add some heat to the bearing races to slip them off the shafts? Upon reassembly, I'd use some wet and dry 320 or 400 paper on the shaft while spinning it in a lathe or something. That is to fit the new bearings first, so they don't bind on the shaft like that. There's no reason for them to be like that.

Good luck and keep us posted.

Rob-♦

|

|

|

|

Post by sokkerbob on Mar 30, 2008 16:22:06 GMT -5

Rob and psj12,

Thanks for the input. Very much appreciated. I have always admired the members of this forum.

Rob stated:

That is why we decided to stop and rethink our battle plan. We are hoping that someone else has gone down this road and confirm what we are finding. We are thinking that maybe the tight bearings contributed to problem with pinion bearing.

Rob stated

That idea is on the table. Problem is that upper shaft and gears are in the way on getting some sort of leverage on the bearing. Also, we want to figure out exactly what happened. We thought we could remove upper shaft, but it appears now that we will have to pull lower shaft with pinion bearing out the back of tractor.

My brother use to have his own auto repair business and has worked on a few tractors so he is pretty good at turning wrenches. We are just scratching our heads trying to figure out best way to continue.

Bob

|

|

FlyHiFlyLo

Administrator  2007 Jinma 554LE

2007 Jinma 554LE

Posts: 425

|

Post by FlyHiFlyLo on Mar 30, 2008 16:30:55 GMT -5

That's a great pic of you and the kids... Wow 5 and two on the way....

|

|

|

|

Post by bracabric on Mar 30, 2008 17:32:08 GMT -5

Great picture of you with the Grandchildren Bob, I am full of envy as whilst being older than you I still don't have any Grandchildren yet,

In hope

Dick

|

|

|

|

Post by sokkerbob on Mar 30, 2008 18:46:51 GMT -5

Thanks for compliments on my grandkids. They all love the tractor. Lots of levers and stuff to yank and push on. All grandpas should have at least one tractor. Looks like more interest in the grandkids. Tractor can wait. Here is one we took last Christmas. From left to right Wesley, George, Sean, Zephyr and Brody  Bob |

|

FlyHiFlyLo

Administrator  2007 Jinma 554LE

2007 Jinma 554LE

Posts: 425

|

Post by FlyHiFlyLo on Mar 31, 2008 1:17:43 GMT -5

Yeah I wished my grandpa had a tractor.

|

|

|

|

Post by sokkerbob on Mar 31, 2008 10:42:25 GMT -5

UPDATE

I just spoke with the mechanic @ Keno Tractors in Oregon. He was very helpful. He has not disassembled any 354 transaxle, but they have done a few 284s.

On the 284's he said the whole thing comes apart. Every nut, bolt, pin. etc. in transmission case and differential. The pinion bearing is first thing that goes in assembly and last thing out in disassembly. He also said that he had to drive most of the bearings off the shafts and out of case. He used a combination of techniques to remove the bearings and destroyed a few bearings in the process.

FYI, I asked him why they had to repair the 284. He said that the bolts that hold the shifter plate has come loose and fell into transmission causing all sorts of damage. So, you folks that have 284's might want to take a good look at that area.

|

|

|

|

Post by Ranch Hand on Mar 31, 2008 17:49:35 GMT -5

Good talking to you today Bob.

Wish I have had more info for you this am. But I think down deep inside we kinda knew that.

Just keep everything need and clean. It is common to have/need to damage bearings sometimes on tearing down gear boxes. Just don't damage gears.

If you see a bearing that you are going to need to get rough with. .... try to get the number off of it before you start talking to it.... know what I mean ?.

Good luck and looking forward to your pic's

Ronald

Ranch Hand Supply

|

|

|

|

Post by sokkerbob on Apr 1, 2008 19:44:12 GMT -5

UPDATE

Brother and I completed disassembly of tractor today. We started around 10:00 am and finished about 4:00 pm. We spent most of our time figuring out best way to tackle problems and keeping things organized.

I took a lot of pictures and will post along with procedures we used to disassemble. (Little tired right now) The biggest problem turned out to be the two bearings on the front of both shafts. Once we removed them, everything else came apart fairly easy.

As I suspected, the circlip in front of pinion bearing was not in its grove which I believe allowed pinion bearing to move forward. I am trying to determine if this was problem in assembly or some force in tractor pushed it out. It would seem that it is assembly related because to my knowledge there have been no other reports of this failure.

Thanks to everyone for your support

Bob

|

|

3RRL

Administrator  Huge Kama

Huge Kama

Posts: 2,027

|

Post by 3RRL on Apr 1, 2008 19:54:25 GMT -5

Bob,

Being assembly related is a good assumption.

You probably didn't read my thread about changing the gear oil on my Kama. I found a brand new tubular dowel pin in there. Luckily the magnet had it secure.

Rob-

|

|